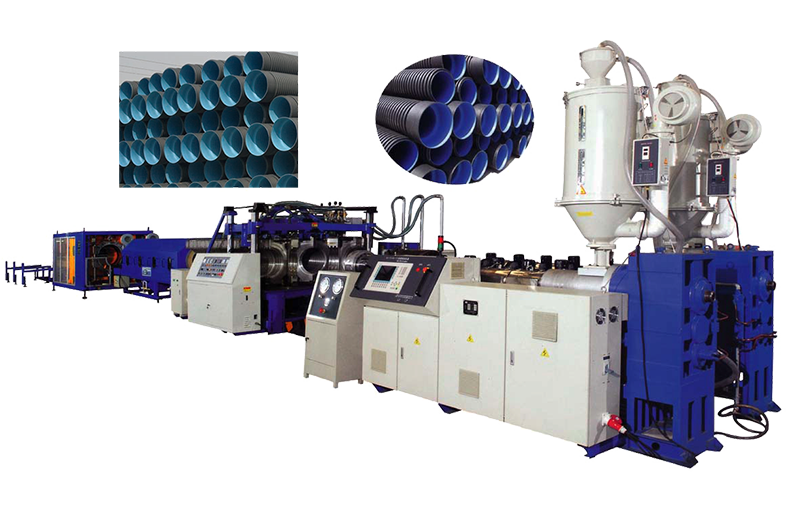

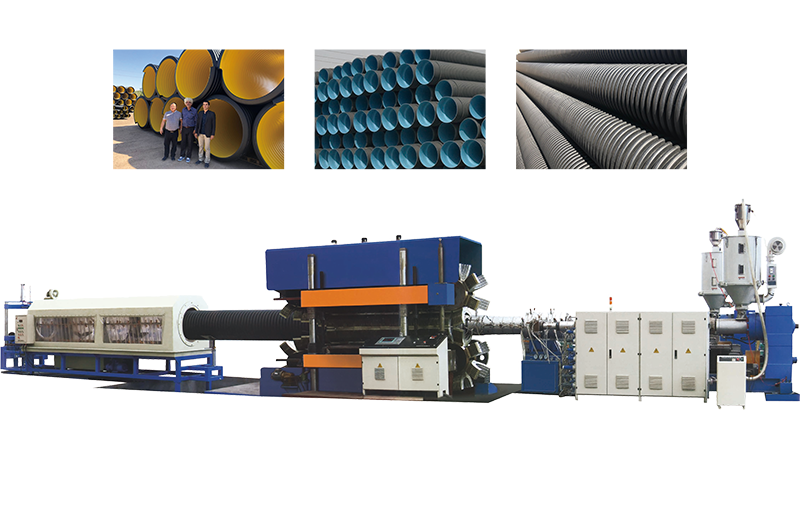

High Speed PE PP (PVC) Corrugated Pipe Extrusion Line

Kufotokozera

Pulasitiki malata chitoliro makina ntchito kubala pulasitiki malata mapaipi, amene makamaka ntchito mu ngalande m'tauni, machitidwe zimbudzi, misewu misewu, minda yosungira madzi ntchito ulimi wothirira, komanso angagwiritsidwe ntchito ntchito mankhwala mgodi madzimadzi mayendedwe ntchito, ndi osiyanasiyana ntchito. Makina opangira zitoliro okhala ndi malata ali ndi maubwino otulutsa kwambiri, kutulutsa kokhazikika komanso kuchuluka kwa automation. The extruder akhoza kupangidwa malinga ndi zinthu zapadera za zinthu wosuta, monga Pe PP kapena PVC. Pe PP iwiri-khoma malata chitoliro extrusion mzere ntchito mtundu watsopano wa mkulu-mwachangu single/mapasa wononga extruder. PVC corrugated mapaipi makina ntchito lalikulu lathyathyathya amapasa kapena conical amapasa extruder. Ndi wosanjikiza umodzi ndi zigawo ziwiri kusankha. Kupanga mapaipi awiri malata pakhoma pali mitundu iwiri,yopingasa iwiri khoma malata chitoliro extrusion mzerendiofukula pawiri khoma malata chitoliro extrusion mzere.

Njira Yoyenda

Zopangira → Kusakaniza → Chowumitsira → Chowumitsira Pulasitiki → Chowumitsira → Extrusion Mould → Kupanga Mold → Makina opangira madzi ozizira →Thanki yamadzi Ozirala →makina odulira →Stacker

Mbali ndi Ubwino wake

1. HDPE imatenga mtundu watsopano wamtundu wapamwamba wa single/twin screw extruder, ndipo PVC imatenga mapasa akulu akulu kapena conical twin extruder. Big conical twin-screw extruder kapena parallel twin-screw extruder amatha kuzindikira pulasitiki yabwino kwambiri pakutentha kochepa komanso kutulutsa kokhazikika.

2. Njira yoziziritsira gawo imakakamizidwa kuziziritsa kwa madzi, komwe kumathandizira kwambiri kuthamanga kwa kuzizira kwa gawo, kuti akwaniritse kupanga kwambiri.

3. Mzere wa chitoliro chamalata umatchedwanso kuti mzere wa makina opangidwa ndi khoma lopangidwa ndi zitoliro ukhoza kuzindikira kuwomba pa intaneti kuonetsetsa kuti zinthu zosiyanasiyana za chitolirocho zikugwirizana ndi miyezo.

4. Kulowetsedwa kwa chiŵerengero chosinthira valavu kumasintha kupanga kupanikizika kokhazikika komanso kodalirika.

5. Chopingasa mtundu corrugator

6. Plateform yogwira ntchito imatha kusinthika katatu.

7. Dongosolo lodzitchinjiriza lodzitchinjiriza limayamba ndipo limagwiranso ntchito limabwereranso ikazima.

8. Makina opangira mafuta

9. Mitsuko ya nkhungu imapangidwa ndi aloyi yapadera ya aluminiyamu ndipo imakhala ndi kulemera kopepuka, mphamvu zambiri, kusagwirizana ndi kuvala bwino, kugwirizanitsa pang'ono powonjezera kutentha.

10. Kuziziritsa kwa mpweya ndi kuziziritsa madzi kuziziritsa nkhungu zamalata zomwe zimapanga chitoliro mwachangu.

11. Makina odulira chitoliro cha malata ali ndi ubwino wolondola kwambiri komanso opanda fumbi.

12. Mzere wathunthu utenga PLC makina olamulira makompyuta omwe amatha kuwonetsa kutentha ndi kupanikizika, kupanga liwiro, alamu yolakwika komanso ali ndi mphamvu zosungirako zoyambira.

Tsatanetsatane

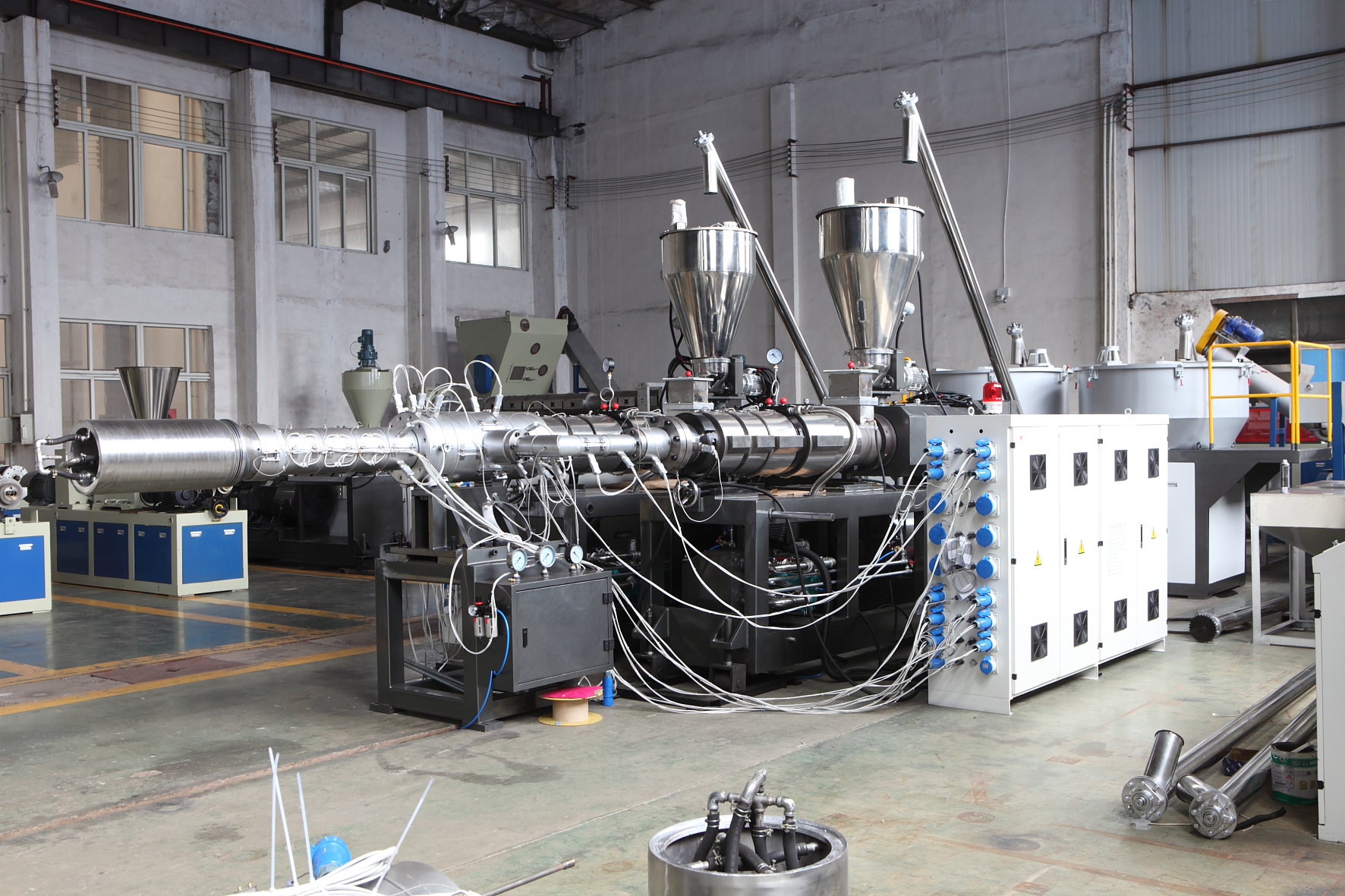

Single Screw Extruder ya PE/PP

Kutengera chiyerekezo cha 33: 1 L/D pakupanga zomangira, tapanga chiŵerengero cha 38:1 L/D. Poyerekeza ndi chiŵerengero cha 33: 1, chiŵerengero cha 38: 1 chili ndi ubwino wa 100% pulasitiki, kuwonjezera mphamvu zotulutsa ndi 30%, kuchepetsa kugwiritsa ntchito mphamvu mpaka 30% ndikufikira pafupifupi liniya extrusion ntchito. Adopt L/D chiŵerengero cha 38:1 wononga kwa zinthu zomwe zili ndi virgin ndi L/D 33:1 screw pa zinthu zobwezerezedwanso.

Simens Touch Screen ndi PLC

Ikani pulogalamu yopangidwa ndi kampani yathu, khalani ndi Chingerezi kapena zilankhulo zina kuti mulowetse mudongosolo.

Spiral Kapangidwe ka Barrel

Kudyetsa gawo la mbiya kugwiritsa ntchito mawonekedwe ozungulira, kuonetsetsa kuti chakudya chili chokhazikika komanso kuwonjezera mphamvu yodyetsa.

Kapangidwe Kapadera ka Screw

Screw idapangidwa ndi mawonekedwe apadera, kuonetsetsa kuti pulasitiki yabwino ndikusakanikirana. Zinthu zosasungunuka sizingadutse gawo ili la wononga.

Mpweya Wozizira wa Ceramic Heater

Chowotcha cha Ceramic chimatsimikizira moyo wautali wogwira ntchito. Mapangidwe awa ndikuwonjezera malo omwe chotenthetsera chimalumikizana ndi mpweya. Kuti mukhale ndi mpweya wabwino wozizira.

Gearbox yapamwamba kwambiri

Kulondola kwa zida kuwonetseredwa giredi 5-6 komanso phokoso lotsika pansi pa 75dB. Kapangidwe kakang'ono koma kokhala ndi torque yayikulu.

Conical Twin Screw Extruder ya PVC

Onse conical wononga wononga extruder ndi parallel twin wononga extruder angagwiritsidwe ntchito kubala PVC. Ndi zamakono zamakono, kuchepetsa mphamvu ndi kuonetsetsa mphamvu. Malinga ndi chilinganizo chosiyana, timapereka mapangidwe osiyanasiyana wononga kuti zitsimikizire kuti pulasitiki yabwino komanso mphamvu yayikulu.

Extrusion Mold

Onse akunja wosanjikiza ndi wamkati wosanjikiza ndi extruded mkati kufa mutu. Njira iliyonse yoyendera mkati mwa mutu wa imfa imayikidwa mofanana. Njira iliyonse imakhala pambuyo pa chithandizo cha kutentha ndi kupukuta galasi kuonetsetsa kuti zinthu zikuyenda bwino. Komanso kufa mutu amapereka wothinikizidwa mpweya pakati onse wosanjikiza. Chombo chowongolera chimagwiritsidwa ntchito kuziziritsa wosanjikiza wamkati kuti apange chitoliro chosalala komanso chosalala mkati. Madzi amphamvu amayenda mkati mwa manja owongolera kuti aziziziritsa bwino. Vacuum imapangidwa pamtunda wa manja owongolera popanga chitoliro chachikulu, kuonetsetsa kuti chitoliro chamkati chimakhala chozungulira.

Kupanga Mold

Makina a CNC amatsimikizira miyeso yolondola. Mpweya wotsekemera wa vacuum ndi njira yoziziritsira madzi yokhala ndi gawo lalikulu lotuluka limatsimikizira kugwira ntchito kokhazikika, kwapamwamba, komanso kogwira mtima. Zida za module ndi aluminiyamu yamphamvu kwambiri, yokhala ndi matenthedwe apamwamba kwambiri, kuuma kwakukulu, komanso kukana kuvala kwambiri. Kapangidwe ka ma module amatengera njira yoponyera yophatikizika, yokhala ndi mawonekedwe owoneka bwino komanso kukhazikika kwamafuta. Mankhwala amkati amtundu wa module amawongolera mphamvu ndi kuuma kwa gawoli, zomwe zimapangitsa kuti pakhale mapangidwe abwino a ma ripples. Chikombolecho chimatengera makina a CNC kuti awonetsetse kuti ndi olondola komanso osalala.

Madzi ozizira Kupanga makina

Makina opangira madzi ozizira amagwiritsidwa ntchito kuyika ndikusuntha nkhungu yamalata, vacuum imapangidwa kuti itenge wosanjikiza wakunja mu nkhungu yamalata kuti apange mawonekedwe a malata. Posuntha nkhungu yamalata, chitoliro chimachotsedwanso ku corrugator.

Automatic Lubrication System

Onjezani mafuta magiya kuti apange nkhungu yamalata kuyenda bwino.

Transmission Gear Rack

Choyikapo giya chimayikidwa pamwamba pa nkhungu yamalata. Zoyika zonse zamagiya zimatsatiridwa ndi chithandizo cha nitriding ndi kutentha, kukana kwanthawi yayitali.

Upper Adjustment System

Sinthani pakompyuta chimango chapamwamba cha kukula kosiyana kwa nkhungu yamalata. Ndi mizati inayi, onetsetsani kusintha kokhazikika komanso kolondola.

Tension Kusintha System

Kuti musinthe kukula kwa nkhungu, pangani nkhungu kuyenda bwino.

Mavavu a Proportional

Kuwongolera mpweya wokhazikika komanso wolondola, kupanga chitoliro chabwino ndi mawonekedwe azitsulo.

Mold Kuzira System

Ndi zonse madzi kuzirala ndi mpweya kuzirala dongosolo, kukhala bwino kuzirala kwenikweni, zabwino ndi mofulumira chitoliro kupanga.

UPS Backup Power

Mphamvu yamagetsi ikalephera, mphamvu yosungira ya UPS idzapereka mphamvu kwa corrugator kuti isunthire chitoliro kuchoka pamanja. Kupewa chitoliro chinamamatira pa mawotchi calibration pambuyo kuzirala chitoliro ndi shrinkage.

Tanki ya Madzi Oziziritsa Utsi

Tanki yozizira imagwiritsidwa ntchito kuziziritsa chitoliro.

Ntchito Yothandizira

Ndi chida chothandizira chokoka, chida chokokeranso chimatha kusintha. Kukoka chitoliro patsogolo.

Quality Utsi Nozzle

Ma nozzles opopera abwino amakhala ndi kuziziritsa bwino komanso sikutsekeka mosavuta ndi zonyansa.

Sefa ya Tanki Yamadzi

Ndi fyuluta mu thanki yamadzi, kupewa zinyalala zazikulu pamene madzi akunja alowa.

Makina odulira mapaipi a malata

Makina odulira chitoliro cha malata ndi olondola kwambiri komanso opanda fumbi.

Chipangizo cha Aluminium Clamping

Ikani chipangizo cha aluminium clamping pamapaipi osiyanasiyana. Kukula kulikonse ndi chipangizo chake cha clamping, palibe chifukwa chosinthira kutalika kwapakati pomwe pamitundu yosiyanasiyana ya chitoliro.

Kalunzanitsidwe dongosolo

Malo odulira amayendetsedwa ndi injini ndi inverter. Panthawi yodulira, malo odulira amayenda molumikizana ndi corrugator kuti apewe kuwonongeka kwa chitoliro.

Kudula Mpeni Pawiri

Ndi mipeni iwiri yodula pamodzi, kuonetsetsa kuti mbali ina ya socket yadulidwa.

Stacker

Kuthandizira ndi kutsitsa mapaipi. Kutalika kwa stacker kumatha kusinthidwa.

Kuthandizira ndi kutsitsa mapaipi. Kutalika kwa stacker kumatha kusinthidwa.

Kuti tisunthe chitoliro chamalata bwino pa stacker, timayika zitsulo zonse zosapanga dzimbiri pamwamba pa stacker.

Kukulunga chitoliro kukhala chodzigudubuza, chosavuta kusunga ndi mayendedwe. Nthawi zambiri ntchito chitoliro m'munsimu kukula 110mm. Khalani ndi single station ndi double station yomwe mungasankhe.

Deta yaukadaulo

| Chitsanzo | Kukula kwa chitoliro (mm) | Extruder | Zotulutsa (kg/h) | Liwiro(m/mphindi) | Mphamvu zonse (KW) | Nkhungu (awiri) | Njira yozizira |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Kuziziritsa mpweya ndi kuziziritsa madzi |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Kuziziritsa mpweya ndi kuziziritsa madzi |