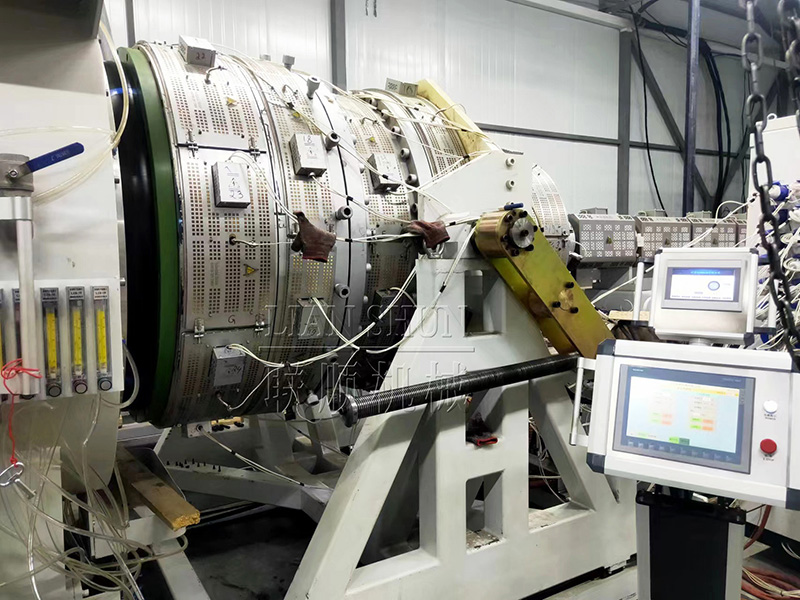

High Speed High Efficient PE Pipe Extrusion Line

Kufotokozera

Makina a chitoliro cha Hdpe amagwiritsidwa ntchito makamaka popanga mapaipi a ulimi wothirira, mipope ya ngalande, mapaipi a gasi, mapaipi operekera madzi, mapaipi otengera chingwe etc.

Mzere wa PE wowonjezera wa chitoliro uli ndi chitoliro chowonjezera, chitoliro chimafa, ma unit calibration, thanki yozizirira, kutulutsa, chodulira, stacker/coiler ndi zotumphukira zonse. Makina opanga chitoliro cha Hdpe amapanga mapaipi okhala ndi mainchesi kuyambira 20 mpaka 1600mm.

Chitolirocho chili ndi zinthu zina zabwino kwambiri monga kutentha kugonjetsedwa, kukalamba kugonjetsedwa, mphamvu zamakina apamwamba, kusokonezeka kwa chilengedwe, ming'alu yabwino, kugonjetsedwa kwabwino, etc. Makina a Hdpe pipe extrusion adapangidwa ndi extruder yapamwamba kwambiri komanso yokhala ndi reducer yomwe imakhala yothamanga kwambiri komanso phokoso lochepa, gawo la gravimetric dosing unit ndi chizindikiro cha makulidwe a akupanga akhoza kusonkhanitsidwa malinga ndi zomwe kasitomala akufuna kuti akwere pamwamba pa mapaipi.

Kutembenuza kiyi njira angaperekedwe, monga laser chosindikizira crusher, shredder, madzi chiller, mpweya kompresa etc. kukwaniritsa apamwamba kalasi ndi basi kupanga chubu.

Njira Yoyenda

Magulu a Raw + Master Batches → Kusakaniza → Chowumitsira → Chowumitsira Pulasitiki → Single screw extruder → Co-extruder ya zingwe zamitundu & Multi Layers → Mold ndi calibrator→ Vacuum Calibration Tank → Utsi Thanki Yamadzi Oziziritsa → Makina Otulutsa → Makina Odulira → Makina Odulira

Mbali ndi Ubwino wake

Makina a chitoliro cha 1.Hdpe amapangidwa ndi ife pogwiritsa ntchito luso lamakono la ku Ulaya ndi luso la R & D la makina apulasitiki kwa zaka zambiri, mapangidwe apamwamba, kapangidwe koyenera, kudalirika kwakukulu, makina apamwamba kwambiri.

2. Hdpe chitoliro extruder ndi wapadera mbiya kudyetsa dongosolo akhoza makamaka kusintha extrusion mphamvu.

3. Kuwongolera koyenera kozizira, pulasitiki yabwino, ntchito yokhazikika.

4. Makina a chitoliro cha Hdpe amatengera dongosolo lolamulira la PLC, pozindikira kulumikizana ndi makina.

5. Mawonekedwe a makompyuta a anthu ndi osavuta kugwiritsa ntchito, osavuta komanso odalirika.

6. Spiral and lattice basket type amafa posankha.

7. Kusintha mbali zina za mzerewu kungathenso kuzindikira zigawo ziwiri ndi zigawo zambiri co-extrusion.

8. Kusintha mbali zina za mzerewu kungathenso kupanga mapaipi a PP, PPR.

Tsatanetsatane

Single Screw Extruder

Kutengera chiyerekezo cha 33: 1 L/D pakupanga zomangira, tapanga chiŵerengero cha 38:1 L/D. Poyerekeza ndi chiŵerengero cha 33: 1, chiŵerengero cha 38: 1 chili ndi ubwino wa 100% pulasitiki, kuwonjezera mphamvu zotulutsa ndi 30%, kuchepetsa kugwiritsa ntchito mphamvu mpaka 30% ndikufikira pafupifupi liniya extrusion ntchito.

Simens Touch Screen ndi PLC

Ikani pulogalamu yopangidwa ndi kampani yathu, khalani ndi Chingerezi kapena zilankhulo zina kuti mulowetse mudongosolo.

Spiral Kapangidwe ka Barrel

Kudyetsa gawo la mbiya kugwiritsa ntchito mawonekedwe ozungulira, kuonetsetsa kuti chakudya chili chokhazikika komanso kuwonjezera mphamvu yodyetsa.

Kapangidwe Kapadera ka Screw

Screw idapangidwa ndi mawonekedwe apadera, kuonetsetsa kuti pulasitiki yabwino ndikusakanikirana. Zinthu zosasungunuka sizingadutse gawo ili la wononga.

Mpweya Wozizira wa Ceramic Heater

Chowotcha cha Ceramic chimatsimikizira moyo wautali wogwira ntchito. Mapangidwe awa ndikuwonjezera malo omwe chotenthetsera chimalumikizana ndi mpweya. Kuti mukhale ndi mpweya wabwino wozizira.

Gearbox yapamwamba kwambiri

Kulondola kwa zida kuwonetseredwa giredi 5-6 komanso phokoso lotsika pansi pa 75dB. Kapangidwe kakang'ono koma kokhala ndi torque yayikulu.

Extrusion Die Head

Extrusion kufa mutu ntchito dongosolo ozungulira, chilichonse otaya njira anayikidwa wogawana. Njira iliyonse imakhala pambuyo pa chithandizo cha kutentha ndi kupukuta galasi kuonetsetsa kuti zinthu zikuyenda bwino. Kufa mutu kapangidwe ndi yaying'ono komanso kupereka kupanikizika khola, nthawi zonse kuchokera 19 mpaka 20Mpa. Pansi pa chipsinjo ichi, chitoliro khalidwe ndi zabwino ndi zotsatira zochepa kwambiri pa mphamvu linanena bungwe. Itha kupanga wosanjikiza umodzi kapena chitoliro chamitundu yambiri.

Kusuntha Chipangizo cha Die Head

Kwa mutu waukulu wakufa, chipangizo chosuntha chimatha kusuntha mutu wakufa kutsogolo ndi kumbuyo, komanso kusintha kutalika kwa mutu wa imfa. Ntchito ndi yachangu komanso yosavuta.

Die Head Rotary Chipangizo

Kwa mutu waukulu wakufa wokhala ndi chipangizo chozungulira, mutu wakufa ukhoza kuzungulira ndi madigiri 90. Mukasintha chitsamba, mandrel, mutu wakufa udzasintha madigiri 90. Angagwiritse ntchito crane kukweza ndi kusintha chitsamba ndi mandrel. Njira iyi ndi yabwino kwambiri.

Chida Chotopetsa Kutentha

Chipangizochi chimawonjezedwa pamutu kuti apange chitoliro chachikulu komanso chokhuthala. Kutulutsa kutentha mkati mwa chitoliro ndi chitoliro chozizira mkati mwa khoma. Kutenthedwa wotopa angagwiritsidwe ntchito kuyanika zopangira.

Chipangizo Chozizira cha Core

Tikapanga chitoliro chokhala ndi mainchesi akulu ndi makulidwe a khoma, tidzagwiritsa ntchito madzi ozizira kapena mafuta oziziritsa kuziziritsa kuziziritsa pachimake cha mutu kuti tipewe kutentha ndikuwonetsetsa kuti zinthu zili bwino.

Tanki ya Vacuum Calibration

Vacuum Calibration thanki imagwiritsidwa ntchito popanga ndi kuziziritsa chitoliro, kuti ifike kukula kwa chitoliro. Timagwiritsa ntchito mawonekedwe a zipinda ziwiri. Chipinda choyamba ndi chachifupi, kuonetsetsa kuti kuziziritsa kwamphamvu kwambiri ndi ntchito ya vacuum. Monga calibrator imayikidwa kutsogolo kwa chipinda choyamba ndipo mawonekedwe a chitoliro amapangidwa makamaka ndi calibrator, kamangidwe kameneka kakhoza kuonetsetsa kuti kupanga ndi kuziziritsa kwa chitoliro mwamsanga komanso bwino.

Kuzizira Kwamphamvu kwa Calibrator

Ndi dongosolo lapadera lozizira la calibrator, lomwe lingakhale ndi zotsatira zabwino zoziziritsa kwa chitoliro ndikuonetsetsa kuti liwiro lalikulu. Komanso ndi nozzle yabwino yopopera kuti ikhale ndi kuzizirira bwino komanso kosavuta kutsekedwa ndi zonyansa.

Thandizo Labwino la Pipe

Kwa chitoliro chachikulu, kukula kulikonse kumakhala ndi mbale yake yothandizira semicircular. Kapangidwe kameneka kamatha kusunga chitoliro chozungulira bwino kwambiri.

Silencer

Timayika silencer pa vacuum adjust valve kuti muchepetse phokoso pamene mpweya ulowa mu thanki yochotsera vacuum.

Vavu Yothandizira Kupanikizika

Kuteteza thanki ya vacuum. Digiri ya vacuum ikafika malire, valavu imatseguka yokha kuti ichepetse kuchuluka kwa vacuum kupewa kusweka kwa thanki. Kuchepetsa kwa digiri ya vacuum kumatha kusinthidwa.

Paipi Yowirikiza Pawiri

Lupu lililonse lokhala ndi makina osefa madzi, kuti apereke madzi ozizira ozizira mkati mwa thanki. Double loop imatsimikiziranso kupereka madzi ozizira mosalekeza mkati mwa thanki.

Madzi, Olekanitsa Gasi

Kusiyanitsa madzi gasi madzi. Gasi wotopa kuchokera pamwamba. Madzi amapita kumunsi.

Full Automatic Water Control

Ndi kuwongolera kutentha kwamakina kukhala ndi kuwongolera kolondola komanso kokhazikika kwa kutentha kwa madzi.

Dongosolo lonse lamadzi lolowera ndi kutulutsa limayendetsedwa mokhazikika, lokhazikika komanso lodalirika.

Chipangizo cha Centralized Drainage

Ngalande zonse zamadzi zochokera ku vacuum tank zimaphatikizidwa ndikulumikizidwa mu payipi imodzi yosapanga dzimbiri. Ingolumikizani payipi yophatikizika ndi ngalande zakunja, kuti ntchito ikhale yosavuta komanso yachangu.

Tanki ya Madzi Oziziritsa Utsi

Tanki yozizira imagwiritsidwa ntchito kuziziritsa chitoliro.

Pipe Clamping Chipangizo

Chipangizochi chikhoza kusintha kuzungulira kwa chitoliro pamene chitoliro chikutuluka mu thanki yopuma.

Sefa ya Tanki Yamadzi

Ndi fyuluta mu thanki yamadzi, kupewa zinyalala zazikulu pamene madzi akunja alowa.

Quality Utsi Nozzle

Ma nozzles opopera abwino amakhala ndi kuziziritsa bwino komanso sikutsekeka mosavuta ndi zonyansa.

Chida Chosinthira Thandizo la Pipe

Thandizo lokhala ndi ntchito yosinthira kuthandizira chitoliro chokhala ndi ma diameter osiyanasiyana.

Pipe Support Chipangizo

Amagwiritsidwa ntchito makamaka popanga chitoliro chokhala ndi mainchesi akulu komanso makulidwe a khoma. Chipangizochi chidzapereka chithandizo chowonjezera ku mapaipi olemera.

Makina Odzaza

Kuchotsa makina kumapereka mphamvu zokwanira zokoka chitoliro mokhazikika. Malinga ndi makulidwe osiyanasiyana a chitoliro ndi makulidwe, kampani yathu isintha liwiro lamayendedwe, kuchuluka kwa zikhadabo, kutalika koyenda bwino. Kuonetsetsa machesi chitoliro extrusion liwiro ndi kupanga liwiro, komanso kupewa mapindikidwe chitoliro pa traction.

Osiyana traction Motor

Chikhadabo chilichonse chimakhala ndi mota yakeyake, ngati injini imodzi ikasiya kugwira ntchito, ma mota ena amatha kugwirabe ntchito. Itha kusankha mota ya servo kuti ikhale ndi mphamvu yokoka yokulirapo, kuthamanga kokhazikika komanso kuthamanga kwamitundu yosiyanasiyana.

Chida Chosinthira Claw

Zikhadabo zonse olumikizidwa kwa wina ndi mzake, pamene kusintha malo a zikhadabo kukoka chitoliro mu makulidwe osiyanasiyana, zikhadabo zonse zidzayenda pamodzi. Izi zipangitsa kuti ntchito ikhale yofulumira komanso yosavuta.

Mapangidwe Osavuta Ogwiritsa Ntchito

Ndi Nokia hard ware ndi mapulogalamu osavuta kugwiritsa ntchito opangidwa ndi kampani yathu. Khalani ndi ntchito yolumikizana ndi extruder, gwiritsani ntchito mosavuta komanso mwachangu. Komanso kasitomala akhoza kusankha zina mwa zikhadabo ntchito kukoka mipope ang'onoang'ono.

Osiyana Air Pressure Control

Chikhadabo chilichonse chokhala ndi kuwongolera kwake kwa mpweya, cholondola kwambiri, kugwira ntchito ndikosavuta.

. Mkulu kukoka mphamvu popanda kutaya mawonekedwe a mapaipi

. Okonzeka ndi 2, 3, 4, 6, 8,10 kapena 12 mbozi malinga ndi ntchito

. Kuyendetsa galimoto ya Servo popereka torque yokhazikika komanso kuthamanga

. Motorized udindo wa m'munsi mbozi

. Ntchito yosavuta

. Chitetezo chotsekedwa kwathunthu kuti chitetezeke kwambiri

. Ma chain conveyors okhala ndi mapepala apadera a labala pamaketani omwe alibe chizindikiro pa chitoliro.

. Kulunzanitsa ndi extruder wononga liwiro amalola kupanga khola pa kusintha liwiro kupanga

Makina odulira mapaipi

Chodulira chitoliro cha pulasitiki chomwe chimatchedwanso makina odulira chitoliro omwe amawongoleredwa ndi Nokia PLC, akugwira ntchito limodzi ndikuchotsa gawo kuti akhale ndi kudula bwino. Makasitomala akhoza kukhazikitsa kutalika kwa chitoliro chomwe akufuna kudula. Zochita zambiri kuti mukwaniritse njira imodzi yodulira (tetezani masamba ndi macheka, pewani kutsamba ndi macheka omwe amamatira chitoliro chokhuthala ndikudulidwa nkhope ya chitoliro ndi yosalala).

Universal Clamping Chipangizo

Ikani universal clamping chipangizo cha miyeso yosiyanasiyana ya chitoliro, osafunikira kusintha kachipangizo kachipangizo kamene kamasintha.

Saw ndi Blade Kusinthana

Ena ocheka amakhala ndi macheka ndi masamba. Kudula kwa macheka ndi masamba kumatha kusinthana makulidwe osiyanasiyana a chitoliro. Komanso, macheka ndi mpeni zingagwire ntchito limodzi pa zofunika zapadera.

Central Height Kusintha

Ndi chipangizo chosinthira magetsi cha clamping chipangizo. Ntchito mofulumira komanso mosavuta. Ndi malire kusinthana kuonetsetsa chitetezo.

. Basi kalunzanitsidwe ndi extrusion liwiro

. Mapulaneti okhala ndi disk ndi chodulira mphero kuti adule ndi kuseketsa

. Zopanda chip zokhala ndi diski kuti zitsimikizire kudula kosalala popanda fumbi

. Touch screen control panel

. Mayendedwe onse amayendetsedwa ndi ma control panel

. Kutsekera kwa mipope pogwiritsa ntchito Universal clamping kuti igwire ntchito mosavuta

. Zosowa zosamalira zochepa

. Makina otsekedwa kwathunthu komanso otetezedwa kuti atetezeke kwambiri

Stacker

Kuthandizira ndi kutsitsa mapaipi. Kutalika kwa stacker kumatha kusinthidwa.

Chitetezo cha pamwamba pa chitoliro

Ndi wodzigudubuza, kuteteza chitoliro pamwamba pamene kusuntha chitoliro.

Central Height Kusintha

Ndi chipangizo chosavuta chosinthira kusintha kutalika kwapakati pamitundu yosiyanasiyana ya chitoliro.

Coiler

Kukulunga chitoliro kukhala chodzigudubuza, chosavuta kusunga ndi mayendedwe. Nthawi zambiri ntchito chitoliro m'munsimu kukula 110mm. Khalani ndi single station ndi double station yomwe mungasankhe.

Kugwiritsa ntchito injini ya servo

Itha kusankha mota ya servo pakusamuka kwa chitoliro ndikumangirira, kulondola komanso kusuntha kwapaipi kwabwinoko.

Deta yaukadaulo

| M'mimba mwake (mm) | Extruder model | Max. Kuthekera (kg/h) | Max. liwiro la mzere (m/mphindi) | Mphamvu ya Extruder (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Zapawiri | SJ60/38 | 460 | 15 × 2 pa | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ 90/38 SJ 90/38 | 1,900 | 0.6 | 280 280 |